Combining Round Wire with Tape Wire

By Christine Errico

INTRODUCTION

This tutorial provides step by step directions on how to light a dollhouse using the Roundwire Hybrid method. I personally find this method to be the most reliable and durable method that allows the wires to be completely hidden.

This tutorial for lighting a dollhouse is for houses that are either not assembled or completely assembled but do not have wallpaper, final coats of paint, flooring, etc. The steps are the same regardless if the dollhouse is assembled or not.

Step 1 - Plan where the tape wire, junction splice, and lights will go

While the house is being "dry fit" (where you assemble the house holding it together with masking tape instead of glue), determine where the lights will go. If your dollhouse is already permanently built, this step would be done before adding wallpaper, flooring or the final coat of paint on the walls.

- Determine where on the dollhouse you want to put the junction splice.

The junction splice should be placed in an area that will allow easy access and clearance for the lead in wire to attach to the splice. Typically junction splices are installed several inches from the bottom of the house at either the side or back (for back open houses). For front open houses, the junction splice is put in the back of the house. Make a small mark (on paper or on the house) where the junction splice will go. - Determine where on the dollhouse you want to run the tape wire.

The tape wire can be placed in an inconspicuous location. You can place the tape wire under the house (usual location) or along the back of the house (for a front opening house). If you place the tape wire under the house, run a little bit of it up the side or back to connect with the junction splice. Make a small mark (on paper or on the house) where the tape wire will be placed. - With the dollhouse in front of you, and pencil and paper, label or number each room.

Examine each room to determine where the lights will go. Sketch the room on paper marking the placement of lights. This sketch will serve as your blueprint for later steps. It will also be kept with the house as a permanent record of the wiring diagram. - Mark with an X on the walls where you want each light/outlet/sconce to go.

With pencil, lightly make an X marking where each light will be attached to the wall. Then carefully look at the room and determine where you will want to run the wires to connect to the main tape wire. Lightly draw a line (or use masking tape) to indicate where the wires will be run to connect to the tape wire. If the wires are to go through ceilings, walls or floors, make a mark (like a circle) to indicate a hole to be drilled and continue the line on the other side. These lines will be your guidelines for making grooves where the wires will lay. - Determine what wires will need to be lengthened.

During the initial planning stages where you make the lines for the wires for each light, determine if the wires that come with the lights are long enough or if they will need to be lengthened. Note this on a separate piece of paper so you can work on lengthening the lights (this step is discussed further down in the tutorial).

Now that you have your lighting diagram made and your lighting locations all planned, it's time to move to step 2, gathering the materials you need.

Step 2 - Gather the Materials you Need

The following is a list of items with a picture to help identify each item that you will need. All of the items can be easily purchased from a local hardware store and/or your local miniature dealer or miniature website shops on the internet.

Special Items Needed - Can purchase at hardware store or through miniature/dollhouse dealers.

Transformer

This connects the power between the dollhouse and the outlet.

Junction Splice

This connects the tape wire to the lead in wire.

Lead In Wire

This connects the junction splice to the transformer.

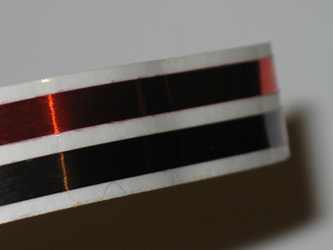

Tapewire

This connects the lights to the electricity.

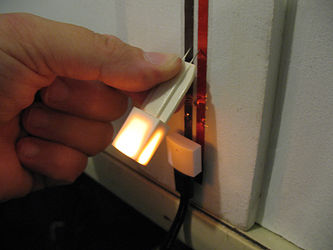

Test Probe

This allows you to test if power is going to the lights

Dollhouse Lights

Soldering Iron

This is used for splicing wires together and connecting to the tapewire.

Solder

Used with the soldering iron to solder.

Tools for making grooves

I use 1/8" drill bit for making the grooves and holes for running wires

Additional Items Needed but not pictured Tweezers, Hammer or rubber mallet, Wet Cloth, Masking Tape, Fire Extinguisher

SPECIAL NOTES:

a. The right type of solder The solder you need is solder for electrical soldering. It is thinner then regular solder and is made for this purpose. The one we use is 0.032 diameter.

b. Tool for making grooves We use a Dremel with a 1/8" drill bit. You can use a hand held drill if you don't have a Dremel, a router with router bit, a can opener, or even a craft knife. Any tool that will make a groove in the plywood will work.

c. Ventilated work area Making grooves, drilling holes, soldering and using liquid electrical tape emits sawdust and fumes. It is important that you work in a ventilated area while soldering and applying liquid electrical tape.

Step 3 - Placing the Tape Wire and Junction Splice on the Dollhouse

In this step, we will place the tape wire and junction splice on the dollhouse and test it to make sure power is going to the tape wire.

- Measure out a length of tapewire.

Take your roll of tape wire and measure out a length that will give you enough room to attach the wires from all the lights. It's easier to make the tape wire longer then you think you will need then to have to add more later on. - Peel back the protective mylar coating that is on top of the tape.

You need the copper tape bare so you can properly solder the wires to the tape. You may have to use a craft knife to separate the mylar coating from the copper strips at one end of the tape. Remove the mylar coating from the entire length of the tape.

- Expose the adhesive backing and apply tape to dollhouse.

Remove the backing that protects the adhesive side of the tape and press the tape in place on the dollhouse. Use a dry rag to smooth out the tape and press it down firmly. - Pound the junction splice into the tapewire.

Using a rubber mallet or hammer with a dry rag wrapped around it (to protect the plastic on the junction splice), carefully pound the junction splice into the tapewire.

- Connect the lead in wire

Connect the lead in wire to the junction splice and transformer. The part of the wire with the two prongs goes into the junction splice while the part with the u-shaped prongs is screwed onto the terminal screws on the transformer. - Test the Connection

Plug the transformer into a regular house outlet and turn on the switch. Using the test probe, touch the prongs to the tape above the junction splice. If the junction splice is properly installed and working, the test probe will light up.

- Remove the test probe, turn off the lead in wire, unplug the transformer from the wall and unplug the lead in wire from the junction splice. This is to make sure there is no electricity going to the dollhouse while you proceed with the next step.

Congratulations! You now you have power going to the dollhouse.

Step 4 - Making the Grooves and Drilling Holes to run the Wires

- Dry fit the light and wire

Look at the room where you are installing the light. You should see the lines you drew in Step 1 where you plan to run the wires. Take the light and "dry fit" the light along the lines to make sure it is acceptable. Now is the time to see if you have to lengthen the wire coming from the light or if it is long enough to reach the tapewire. If you have to lengthen the wire from the light, follow our tutorial at the bottom of this page on Splicing Wires Together. - Drill the Hole and Groove

Using your Dremel with a drill bit, or other tool to make the groove (a pointed can opener works also, but is slightly more difficult), make a groove either in the floor or ceiling where you are going to run the wire. First, make the groove with the Dremel OFF. This will etch the wood lightly and provide better control when you make the groove with the Dremel on. Next turn the Dremel on and slowly use the Dremel to create the groove. Hold onto the Dremel tightly since it will want to swerve out of your hands. Don't worry about making the groove too deep at first, you can always go back and make it deeper on a second and third pass. After you make the groove, drill the hole where you will feed the wire to the tapewire.

- Once the hole and groove are made, clean out the sawdust and sand the groove smooth.

- If the wires are going along a wall, you can run the wires behind baseboard or molding thereby eliminating the need to drill grooves in the walls.

Move onto Step 5 - Installing the Lights

Plug in your soldering iron so it heats up while you are doing the next few preparations. While your soldering iron is heating, make sure the area around it is clear so it does not burn the work surface or anything nearby. Use the stand that came with the soldering iron to protect the work surface.

- Test light to be installed - OPTIONAL

Even though this step is optional step, it's a good idea to test the lights so you if they don't work after installation, you know the light was working beforehand and it could help with troubleshooting.

To test the light, using the socket strip, attach the prongs of the strip to the transformer with a screwdriver and plug the light into the strip. Turn on the socket strip and the lights should work. Turn on the socket strip and the lights should work. If the lights don't work, first try replacing the fuse in the socket strip. If the fuse is good and the lights don't work, you may have a bad bulb. Try replacing the bulb in the light. If you don't have a socket strip, you can test the light when you remove the plug to prepare it for soldering. - Remove plug from the end of the light.

The plug needs to be removed feeding through the dollhouse walls and for soldering to the tapewire. To do this, take your tweezers and gently pull off the brass points that are on the end of the plug. Push the bare wire through the plug head and pull the plug head off the wires.

- Thread the Wire to The Tapewire

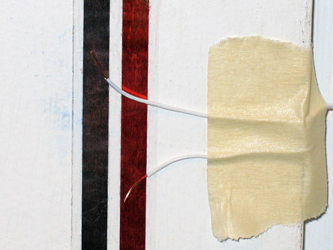

Feed the wire through the hole you made in the dollhouse until it reaches the tapewire. If the wire is too long, trim it to take up any slack. You don't want to have too much excess lose wire that could get caught on something. Make sure you do not pull the wire too tight however. - Lay the Wire in the Grooves

Place the wire in the grooves but do not glue it in. Use masking tape to hold the wire in the grooves. Use masking tape to hold the light fixture in place at the point where it will be permanently installed. Do not remove the adhesive backing from the light fixture and attach it permanently yet.

Secure the Newly Threaded Wire (If you are using the socket method, proceed to Step 5 A)

Using masking tape, secure the strands of the wire near, but not over the tapewire. Put one wire over the blue copper tape and one wire over the orange copper tape. Make sure the wires are not too long. If the bare wires are too long, cut them to about 1/4 of an inch long. If the white wire is too long, trim that and remove the insulation on the wires to expose the bare copper wires.

Make sure the bare wires from one strand covers only the blue side of the tape and bare wires from the other strand cover only the copper side of the tape.

If the wire is too short and needs to be lengthened, see the instructions for lengthening wires at the bottom of this tutorial.

- Test the Light

If you haven't already done so, you can test the light by plugging in the junction splice and transformer. Make sure both ends of the wire touch the tape. You may have to hold the wire down with your fingers by pressing lightly on the insulated (white) part of the wire. The light may flicker, this is ok, since the connection is not secure. You just want to make sure it lights up. When it does, remove the wire, unplug the lead in wire and transformer and move onto the next step. - Prepare for Soldering

You are now ready to begin soldering the ends to the tapewire. Plug in your soldering iron and wait for it to heat up if you haven't already done so.

DO NOT let the ends of the wire touch each other when the electricity

is going to the dollhouse - this will cause a short in the wires!

Move onto Step 6 - Soldering the wires

Step 6 - Soldering the wires

NOTE: Before beginning with this step, make sure your work area is well ventilated! Soldering will create fumes that are not advisable to inhale.

Note: Soldering is a skill that may take some practice to learn. Do not be discouraged if you don't get it on the first attempt. It is recommended that you try splicing wires together to get practice soldering.

Soldering also occurs rather quickly so it is recommended that you read the next few sub steps thoroughly so you can do them without having to refer back to the written steps.

- Strip the insulation

If there is not enough copper wire showing at the end of the strands of wire, you may have to strip the insulation. To do this, take one strand of wire from the light and using your thumb fingernail, pinch the white insulation over one of the strands of wire and pull. This will pull the insulation off without breaking the wires. You want to have about 1/4" of bare wires showing to give you enough wire to solder to the tapewire. Strip the insulation from each strand separately. - Begin Soldering

Take your soldering iron and touch it lightly to the wires that are resting against the tapewire. You want to heat the copper tapewire and the wires from the light.

- While you are still heating the wires with the soldering iron, take your spool of solder and touch it to the heated wires. Do not touch the solder directly to the iron.

- The solder will flow on the area. Let the solder flow until it adequately covers the wires. Think of the solder like glue. You don't want to apply too much or you'll have a large bump. A little is all you need to make the connection and hold the wires down.

- After the desired amount of solder flowed onto the wires and tape, remove the solder then remove the iron. Let the solder harden (about 1-3 seconds).

- Double check to make absolutely sure the bare wires are NOT touching each other after they were soldered. If they are, when you turn the electric on to the dollhouse, the wires will short out.

That's all there is to it! You successfully soldered the lighting wires to the tapewire. Now you are ready to test the connection.

Step 7 - Testing the newly soldered connection

MAKE SURE the ends of the wires are NOT touching each other BEFORE turning the electricity on to the dollhouse

- Provide electricity to the dollhouse

Attach the lead in wire to the junction splice, plug in the transformer and turn on the power. The light you just installed should now be lit. If it is, CONGRATULATIONS! You are nearly finished.

- Troubleshooting non-working lights

If the light is not lit, then it is possible that the soldering was not done properly. Double check the solder to make sure you soldered all the tiny fine wires to the tapewire. If there are any loose wires, you will have to resolder them by heating up the solder, using tweezers to push the wire into the solder and letting the solder set again.

Step 8 - Finalizing the light installation

- Permanently attach the light

Glue the wires into the grooves and permanently attach the light to the wall or ceiling. - Finish off the Groove

Finish off the groove by filling it in with wood filler or spackle. Be careful sanding the groove that you filled with spackle or wood filler. You don't want to sand the insulation away from the wires and accidentally sand the wires and break the connection. - If the tapewire was run under the house, you do not need to do anything else. You can leave it exposed, or if you prefer, you can put a plain white sheet of heavy cardstock or paper over it. It is safe to cover the tapewire and soldered connections.

Congratulations! You successfully installed lights in your dollhouse. Repeat the following steps for each light you wish to install in your dollhouse and enjoy your newly lighted dollhouse!

Bonus Tutorial!! How to lengthen wires on dollhouse lights!

How to lengthen wires on dollhouse lights.

If you have a light where the wire is too short to reach to the tapewire or socket/power strip, you can extend the wire by splicing extra wire onto the existing wire. Splicing wire together is easy with the proper tools and a bit of patience.

Step 1 - Gather the Materials you Need

The following is a list of items with pictures to help identify each item that you will need. All of the items can be easily purchased from a local hardware store and/or your local miniature dealer or miniature website shops on the internet.

Liquid Electrical tape

Used for protecting newly soldered wires and splices.

Soldering Iron

This is used for splicing wires together and connecting to the tapewire.

Solder

Used with the soldering iron to solder.

Extra Wire - 32 gauge

This is used for lengthening wires on lights.

Light that needs to be lengthened

Additional items needed but not pictured:

tweezers, masking tape, clamp, wet cloth, fire extinguisher

Step 2 - Remove plug and strip insulation from wire

Plug your soldering iron in so it can heat up while you do the next step.

- Remove the plug from the light

The plug needs to be removed to expose the bare wires to be spliced together. To do this, take your tweezers and gently pull off the brass points that are on the end of the plug. Push the bare wire through the plug head and pull the plug head off the wires. - Measure the length of wire

Take the spool of wire and measure a length of wire you need to extend the existing wire. Remember, you can always shorten the wire but it's more difficult to add on so make sure you make the extension long enough. - Stagger the cuts

Trim one of the strands of wires on the light about an inch or so shorter then the other one. Do the same thing for one of the strands of wires on one end of the extension. This will stagger the splices to reduce the chance of creating any shorts when the wires are spliced together. This will also reduce any bulk from having both wire spiced together at the same point.

- Strip the insulation

Take one strand of wire from the light and using your thumb fingernail, pinch the white insulation over one of the strands of wire and pull. This will pull the insulation off without breaking the wires. You want to have about 1/2" of bare wires showing to give you enough wire to solder together. Strip the insulation from each strand separately. You will have to do this on both strands of one end of the the wire extension and on both strands of the wire from the light.

With your tweezers, twist each end to make sure the fine wires are gathered up together. This will help with soldering and with splicing wires together.

Step 3 - Prepare the wires for soldering

- To prepare the wires for soldering, we are going to use a technique called "tinning" the wires. What this does is apply solder to each end of the wire to make it easier for them to be soldered together and reduces the amount of solder you have to apply when soldering the ends together.

- Take one wire (it doesn't matter what one) and put it between a clamp. This will hold the wire while you solder it together. You need both hands to hold the soldering iron and solder. You could also have someone hold the wire for you, but a clamp is easier and probably more handy then a second pair of hands.

- Take your soldering iron and solder. Touch the soldering iron to the bare ends of the wire for about 1-2 seconds. Then touch the tip of the solder to the wires, not the soldering iron. If the wires are hot enough, the solder should flow between the wires.

- Do not hold the soldering iron to the wires too long or you will melt the insulation on the wires. After the solder flowed onto the wires, remove the solder then the soldering iron. Repeat the process until all four wires are tinned.

Step 3a - Solder the Wires together

- Match the long end of one strand of wire from the light with the short end of a strand of wire from the extension. Using your tweezers, gently twist the wires together to hold them while you solder. Use your clamp to hold the extension wire as you did while tinning the wires.

- Take your soldering iron and heat the solder that is on both strands of wires. If you properly tinned the wires, you will see the solder melt together. Remove your soldering iron and let the solder set (about 1-2 seconds).

Repeat this process to solder the other strands together.

Step 3b - One strand of wire Soldered Together

Both strands of wires soldered together extending the length of the wires.

Step 4 - Apply Electrical Tape to Secure the Solder

- Once the solder has set on all four strands, take your liquid electrical tape and dab a bit on each of the soldered joints. Let that dry (about 5-10 minutes). This provides an added layer of insulation to the soldered joints.

Step 5 - Test the Lights.

- If you are using the socket/powerstrip method to light your dollhouse, thread the wires through the room out the side of the dollhouse by the socket/powerstrip. Reattach the plug to the bare end of the extension wire.

- If you are using the roundwire hybrid method, thread the wire through the room and solder to the tapewire.

- Turn on the power to the dollhouse to test the lights.

Congratulations! You successfully extended the wires on the lights in your dollhouse.